Development of embedded product is usually a challenge. You can face it on your own or find a trusted partner that already has this experience. We have gained such expertise when we built our products and can help you to build yours.

Device development lifecycle

Each and every device starts from an idea, but not every idea leads to a successful product. Unless it is something life-changing, initial goal needs to be first tested on potential customers to ensure it is necessary for somebody else than a creator. The most inexpensive and quick approach is to build a minimum viable product (MVP) which contains just a few key features of a future product. MVP is usually built using development boards but can sometimes be a prototype with custom hardware. The general recommendation is to spend as little time and resources as possible to build a prototype. Each MVP is tested on potential customers, then improved and tested again. This lasts until you have found a niche for your product and you clearly understand who your customers are and why they would use your product. MVP testing is usually an iterative process and takes several cycles before you are ready to proceed to the next step.

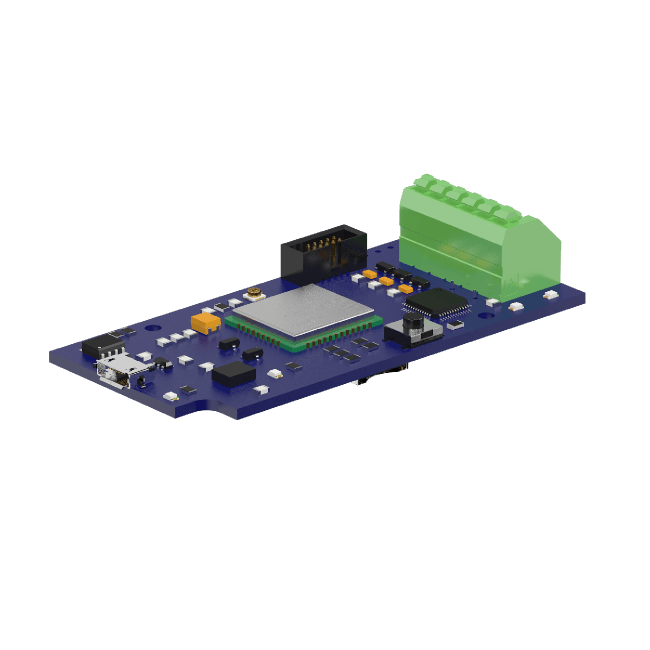

The next step is the actual development that involves hardware, firmware, mechanical, WEB and/or mobile design of the product. The outcome of this phase is the source code and hardware design files which are ready to be used for manufacturing. Before going to full scale production it is strongly recommended to create the first batch of devices and thoroughly test them to ensure the product exactly matches the requirements. Early customers are good candidates for beta units as their feedback is very valuable and may help to improve the product before resources are wasted.

When all tests are done, manufacturing process starts, which is the most exciting step in device development. In most cases, this phase involves PCB assembly, manufacturing of mechanical parts, device assembly, testing, certifications and packaging.

Finally, all devices enter support phase which foresee device improvement with bug fixes and new features.

Technologies we use

Microcontrollers/Platforms:

- ST STM32

- Nordic NRF

- Cypress PSOC

- Atmel AVR

- Microchip PIC

- Arduino

- Espressif ESP

- RaspberryPI

WEB:

- PHP 7

- MYSQL

- Laravel

- Redis

- REST API

Firmware update:

- Bootloaders

- DFU

- FOTA

Real-time operating systems:

- FreeRTOS

- ChibiOS

Sensors:

- Temperature

- Humidity

- Light

- Pressure

- Sound

- Accelerometer/gyroscope

- DC/AC engine, solenoid

- Hall sensor

- RTC

- IR sensor

- Ultrasonic sensor

- Touch sensor

Communication protocols:

- BLE

- WiFi

- Ethernet

- GSM/LTE

- GPS

- USB

- RFID/NFC

- UART

- I2C

- SPI

- CAN

PCB design:

- Altium

- Eagle CAD